In the world of building design and construction, fenestration plays a crucial role in enhancing the aesthetics, functionality, and energy efficiency of a structure. Fenestration refers to the arrangement and design of openings in a building, including windows, doors, skylights, and curtain walls. Fenestration plant operations encompass the manufacturing, quality control, safety measures, and technological advancements involved in the production of these essential building components.

Understanding Fenestration Plant Operations

Before delving into the intricacies of fenestration plant operations, let’s gain a better understanding of the key components involved in this process.

Key Components of Fenestration Plant Operations

There are several essential components within fenestration plant operations that contribute to the overall success and efficiency of the manufacturing process. These include:

- Design: Fenestration plant operations begin with the design phase, where architects and engineers collaborate to create innovative and functional window and door systems that meet the specific requirements of a building.

- Raw Materials: High-quality raw materials, such as glass, aluminum, vinyl, and wood, are carefully selected to ensure the durability, energy efficiency, and aesthetic appeal of the final fenestration products.

- Manufacturing Process: Fenestration manufacturing involves a series of steps, from cutting and shaping the materials to assembly and glazing, which we will delve into later in this guide.

- Quality Control: To ensure the consistent quality of fenestration products, stringent quality control measures are implemented at various stages of the manufacturing process.

- Safety Measures: Fenestration plant operations prioritize the safety of workers by implementing safety protocols, providing proper training, and equipping the facility with necessary safety equipment.

- Technological Advancements: The advent of technology has brought about significant advancements in fenestration plant operations, enabling improved efficiency, precision, and sustainability.

The Role of Fenestration in Building Design

Now that we have a basic understanding of fenestration plant operations, let’s explore the vital role fenestration plays in building design.

Fenestration not only enhances the visual appeal of a structure but also plays a critical role in the energy efficiency and overall performance of a building. Well-designed windows and doors allow natural light to flood into the interior, reducing the need for artificial lighting and contributing to occupant comfort. Additionally, properly insulated fenestration systems help maintain stable indoor temperatures, resulting in lower energy consumption for heating and cooling.

Architectural fenestration can also accentuate the unique design elements and character of a building while providing functional benefits such as ventilation, daylighting, and noise reduction.

The Process of Fenestration Manufacturing

With a solid foundation in the key components of fenestration plant operations, let’s dive into the intricate process of fenestration manufacturing.

Raw Materials in Fenestration Manufacturing

The selection of appropriate raw materials is essential to produce high-quality fenestration products. Here are some commonly used materials:

- Glass: Various types of glass, including float glass, tempered glass, and insulated glass units (IGUs), are utilized to achieve specific performance characteristics such as thermal insulation, soundproofing, and security.

- Aluminum: Lightweight yet strong, aluminum is a popular choice for window and door frames due to its durability, corrosion resistance, and versatility in design.

- Vinyl: Vinyl windows and doors offer excellent energy efficiency, low maintenance requirements, and a wide range of design options.

- Wood: Wood provides a natural and timeless aesthetic, offering exceptional insulation properties and design flexibility.

Steps in the Fenestration Manufacturing Process

The fenestration manufacturing process consists of a series of steps that transform raw materials into fully functioning windows, doors, and other fenestration products. Here are the key steps involved:

- Design and Planning: Architects and engineers collaborate to create detailed fenestration designs that meet the project requirements and code regulations.

- Cutting and Shaping: Raw materials are carefully measured and cut into precise shapes required for the specific fenestration components.

- Assembly: The different fenestration elements, such as frames, glass panes, and hardware, are skillfully assembled, ensuring precise alignment and proper sealing.

- Glazing: Glass panes are installed, sealed, and secured within the fenestration frames to provide structural integrity, weather resistance, and thermal insulation.

- Finishing Touches: The final fenestration products undergo finishing touches such as painting, staining, or coating to enhance their visual appeal and protect against environmental factors.

- Quality Control Testing: Stringent quality control measures, including performance testing and inspections, are conducted throughout the manufacturing process to ensure the fenestration products meet industry standards.

Quality Control in Fenestration Plant Operations

Now that we have explored the manufacturing process, let’s shift our focus to the crucial aspect of quality control in fenestration plant operations.

Importance of Quality Control

Quality control is a vital component of fenestration plant operations as it ensures the consistent production of superior products that meet or exceed industry standards and customer expectations. A robust quality control system helps minimize defects, enhance durability, and optimize energy efficiency in fenestration products.

By implementing rigorous quality control measures, manufacturers can identify and rectify any issues or deviations early in the manufacturing process, preventing costly rework, warranty claims, and dissatisfied customers.

Quality Control Techniques in Fenestration

Several quality control techniques are employed in fenestration plant operations to uphold product quality and performance. These include:

- Dimensional Accuracy Checks: Precision measurements are taken at various stages of manufacturing to ensure the fenestration components adhere to the specified dimensions and tolerances.

- Performance Testing: Fenestration products undergo rigorous testing for factors like air and water infiltration, structural integrity, thermal insulation, and sound transmission to assess their performance capabilities.

- Visual Inspections: Skilled inspectors visually examine the fenestration products to identify any surface defects, finishing imperfections, or signs of inadequate assembly.

- Third-Party Certifications: Manufacturers may seek certifications from reputable organizations to validate the quality, integrity, and compliance of their fenestration products.

Safety Measures in Fenestration Plant Operations

Ensuring the safety of workers and maintaining a secure working environment are paramount in fenestration plant operations.

Common Safety Hazards and Their Prevention

Fenestration manufacturing involves various hazards that can be minimized or eliminated through the implementation of proper safety measures. Some common safety hazards in fenestration plant operations include:

- Machine Hazards: Proper machine guarding, regular maintenance, and operator training are essential to prevent accidents caused by moving machinery parts.

- Material Handling: Ergonomic practices, including the use of lifting equipment and training in safe lifting techniques, reduce the risk of musculoskeletal injuries during material handling.

- Hazardous Substances: Adequate ventilation, the use of personal protective equipment (PPE), and adherence to proper handling procedures mitigate the risks associated with hazardous substances like adhesives, paints, and solvents.

- Slips, Trips, and Falls: A clean and organized workplace, proper signage, and non-slip flooring help minimize the risk of slips, trips, and falls.

Safety Equipment and Procedures in Fenestration Plants

Fenestration plants are equipped with safety equipment and implement procedures to ensure a safe working environment. Some common safety equipment and procedures include:

- Personal Protective Equipment (PPE): Workers are provided with appropriate PPE, including safety glasses, gloves, hard hats, and hearing protection, to safeguard against potential hazards.

- Emergency Response Planning: Fenestration plants have comprehensive emergency response plans in place to address potential emergencies such as fires, chemical spills, or injuries.

- Training Programs: Regular safety training sessions and drills are conducted to educate workers about potential hazards, safe practices, and proper operation of equipment.

- Maintenance and Inspections: Regular maintenance and inspections are carried out to ensure the proper functioning of machinery, electrical systems, and safety equipment.

Technological Advancements in Fenestration Plant Operations

Technological advancements have revolutionized fenestration plant operations, enhancing efficiency, precision, and sustainability.

Impact of Technology on Fenestration Manufacturing

Technology has transformed fenestration plant operations, bringing forth groundbreaking innovations that streamline manufacturing processes and drive superior product performance. Some key technological advancements include:

- Computer-Aided Design (CAD): CAD software enables architects and engineers to create intricate fenestration designs and simulate their performance characteristics before production.

- Automated Manufacturing Systems: Robotics and automation technologies have simplified and accelerated fenestration production, reducing labor-intensive tasks and minimizing errors.

- Sustainable Materials: The introduction of sustainable materials such as low-E glass, recycled aluminum, and composite materials has made fenestration products more energy-efficient and environmentally friendly.

- Energy-Efficient Glazing Technologies: Advanced glazing technologies, such as smart glass and thermally broken frames, improve energy efficiency by mitigating heat transfer and maximizing daylight utilization.

Future Trends in Fenestration Technology

As fenestration technology continues to evolve, several exciting future trends are emerging:

- Smart Fenestration: Integration of fenestration systems with smart sensors, automation, and energy management systems will optimize energy efficiency and enhance user comfort.

- Energy-Generating Glazing: Researchers are working on developing fenestration products that generate renewable energy, such as transparent solar panels integrated into windows.

- Biophilic Design: Incorporating natural elements in fenestration design, such as green walls and living windows, creates healthier and more aesthetically pleasing indoor environments.

- Structural Glass: Advancements in glass technology allow for the creation of larger, frameless structural glass facades, offering uninterrupted views and architectural freedom.

As we conclude our ultimate guide to fenestration plant operations, it is evident that fenestration plays a vital role in building design, energy efficiency, and occupant comfort. By understanding the key components of fenestration plant operations, the manufacturing process, quality control techniques, safety measures, and technological advancements, we gain a holistic understanding of this dynamic industry. Continued innovation and a commitment to excellence will ensure that fenestration plants meet the demands of today’s architectural landscape while paving the way for a sustainable and technologically advanced future.

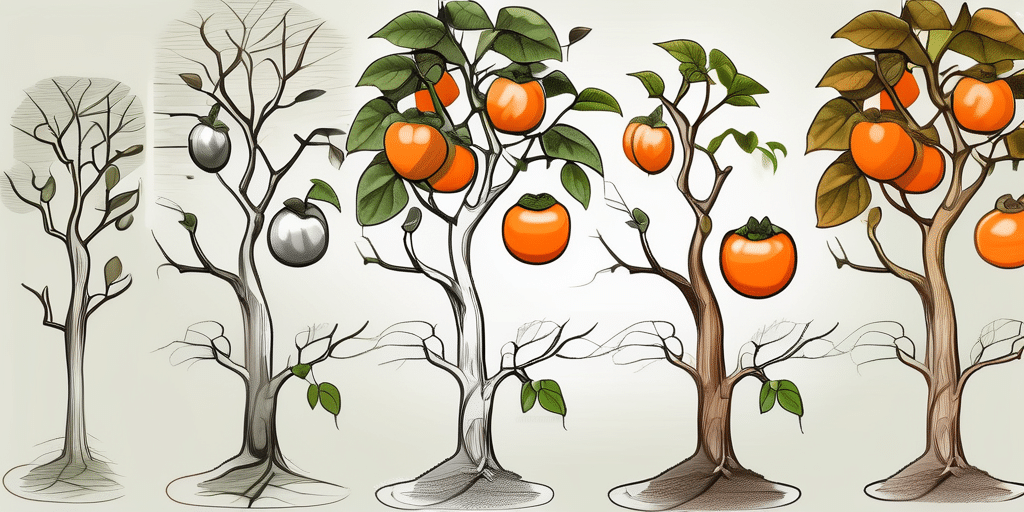

Extend Your Passion for Design to the Garden

Just as fenestration is essential to the beauty and efficiency of your home, the right gardening choices are key to cultivating your ideal outdoor space. If you’re inspired by the innovation and attention to detail in fenestration plant operations, you’ll love the tailored gardening insights from How to Grow Everything. Subscribe for free to learn how to build the garden of your dreams with personalized advice that considers your location, grow zone, and experience level. Join our family of gardening enthusiasts and receive the best tips, deals, and special offers directly to your inbox—100% free, with no spam. Let’s grow together!